Visual Design & Guide

Design Approach: Started with a defined array of fonts, colors, and styles from the current brand guide. These served as inspiration for all proposed solutions and designs.

App Concepts & Screens

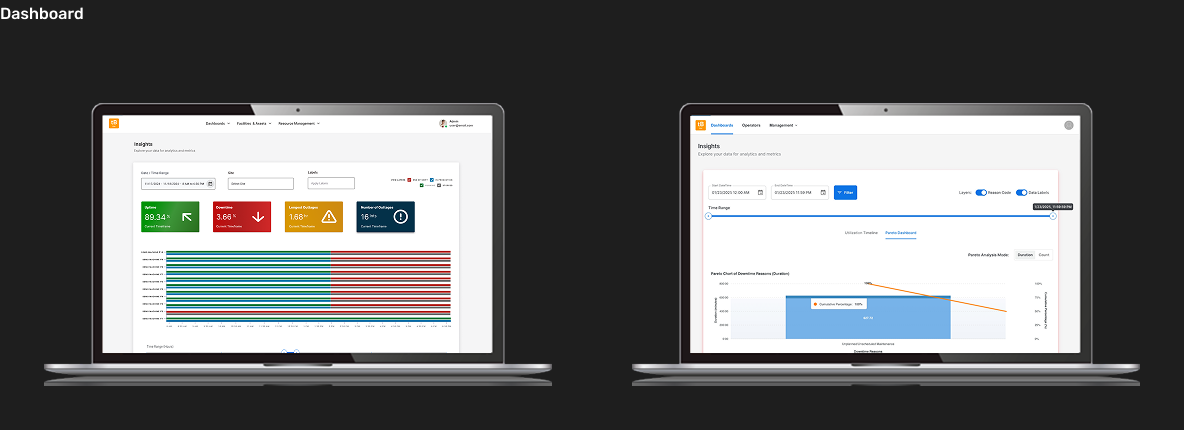

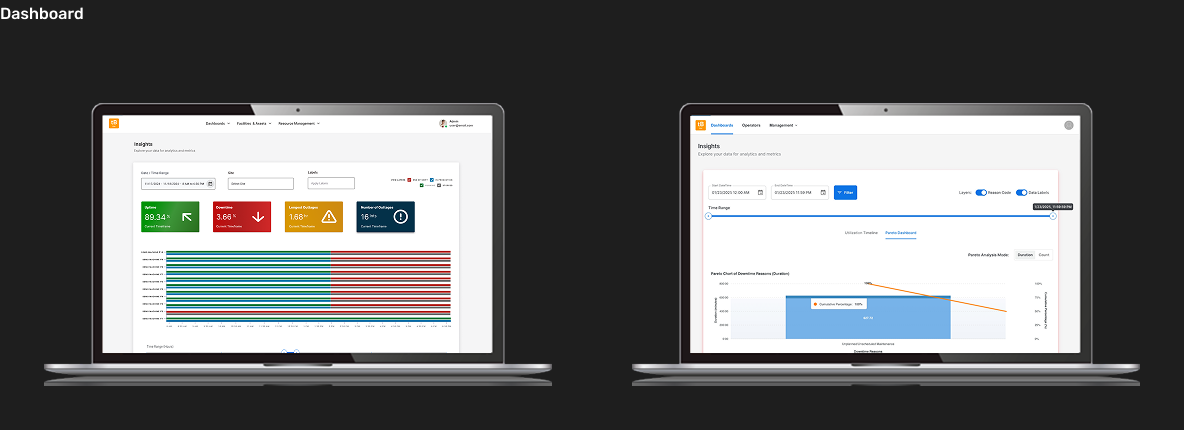

Build a data-driven analytics platform purpose-built for legacy analogue industrial and manufacturing environments.

Manufacturing facilities across North America were struggling with critical operational blind spots. Plant managers relied on outdated paper-based systems to track machine uptime, creating a cascade of inefficiencies: lost documentation, delayed incident reporting, and reactive maintenance strategies that cost facilities thousands in unplanned downtime.

We identified a significant market opportunity in the manufacturing sector, where digital transformation had largely bypassed shop floor operations. Despite Industry 4.0 advances, most facilities still use clipboards and manual logs to track their most expensive assets—production machinery.

Design and develop a comprehensive digital machine uptime tracking platform that seamlessly transitions manufacturing teams from paper-based logging to real-time, data-driven operations.

Create a web/tablet app interface simple enough for operators with minimal tech experience and for low friction in noisy, industrial environments

Ensure mobile functionality in harsh manufacturing environments

Deliver immediate value to justify rapid ROI expectations

Build scalable architecture to accommodate facilities of varying sizes

Design workflows that integrate with existing maintenance protocols and have an easy analogue to digital data capture capabilities

One-tap machine up/down reporting with automated timestamps

Touch-optimized interface with glove-friendly targets for factory floor use

Pareto charts and trend analysis for pattern identification

Offline capability and role-based access control

System optimized for various manufacturing lighting conditions

Design Approach: Started with a defined array of fonts, colors, and styles from the current brand guide. These served as inspiration for all proposed solutions and designs.

"Tiber transformed how we think about our machines. Instead of fighting fires, we're preventing them."

— Manufacturing Director, Automotive Parts Facility

"The mobile app fits perfectly into our workflow. Operators love how fast it is."

— Maintenance Manager, Food Processing Plant

"Tiber transformed how we think about our machines. Instead of fighting fires, we're preventing them."

— Manufacturing Director, Automotive Parts Facility

"The mobile app fits perfectly into our workflow. Operators love how fast it is."

— Maintenance Manager, Food Processing Plant